|

MATERIALS MODELLING LAB Department of Materials Engineering School of Engineering The University of Tokyo |

| Index Research Publication & Presentation Member Awards Class Access |

|

last update, 12 Sep, 2024

RESEARCH (selected)

1. Prediction of materials structures and properties with generative models

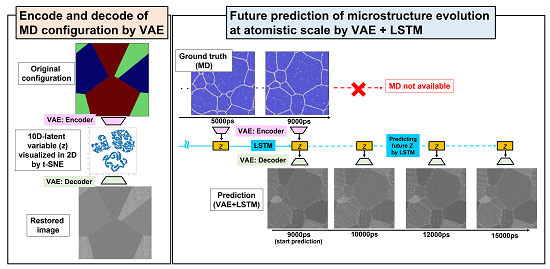

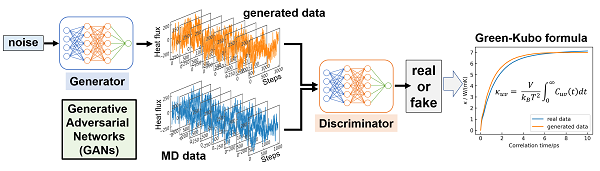

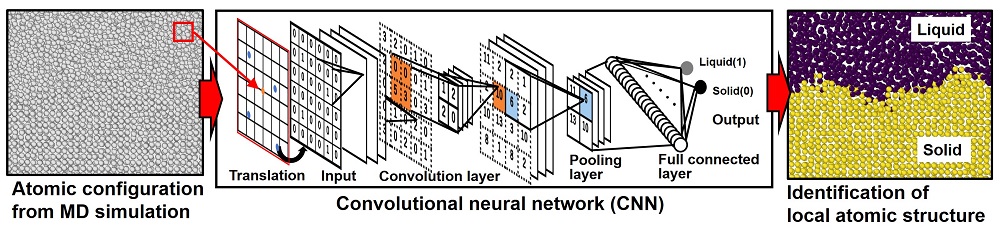

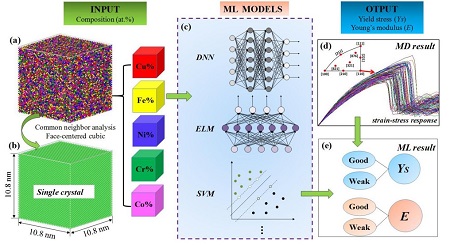

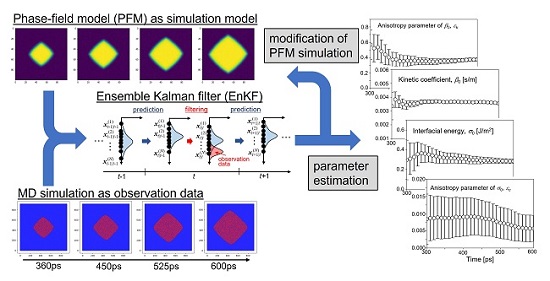

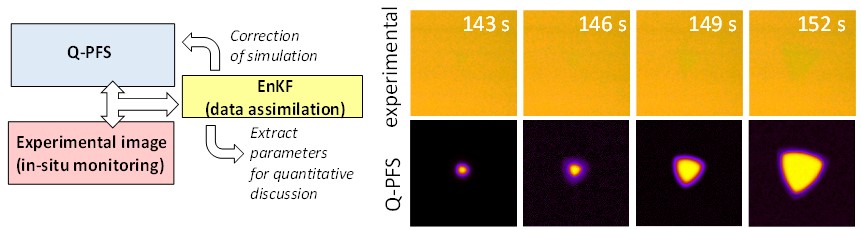

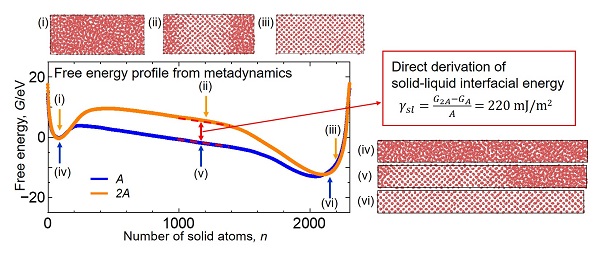

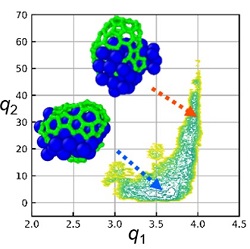

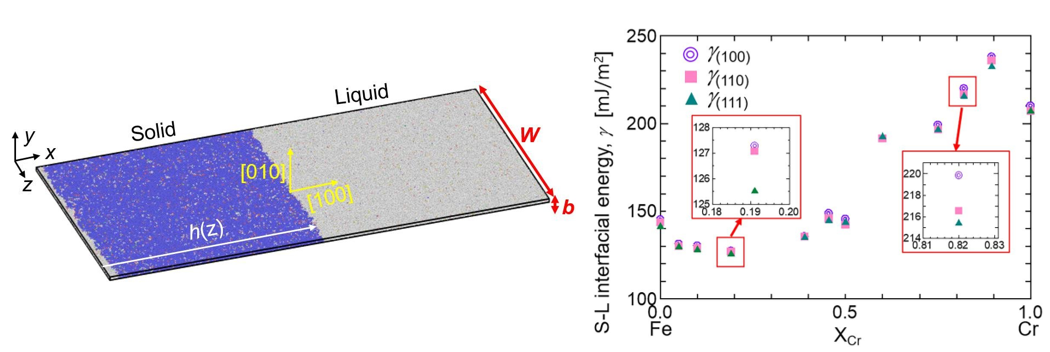

2. Machine learning approach to MD configuration and related materials properties 3. Large-scale MD simulation of nucleation and microstructure formation 4. Numerical simulation for pattern formation dynamics 5. Bayesian data assimilation for esimation of materials properties 6. Metadynamics-based simulation for free energy survey 7. Acceleration of MD simulation with parallel CVHD method 8. Solid-liquid interfacial properties from MD-based simulation 9. Interaction of graphenes with a turbostratic orientational relationship 10. Metal-catalyzed growth of carbon nanotubes and graphene Prediction of Materials Structures and Properties with Generative Models A novel method to predict multi-atom cooperative phenomena at atomic scale is proposed based on a deep generative model in combination with recurrent neural network. Microstructure evolution of the polycrystalline iron is successfully predicted through (i) dimensionality reduction of atomic coordinates using variational autoencoder (VAE), (ii) time evolution of latent variables using long short term memory (LSTM), (iii) data restoration using VAE decoder.  K. Sase, Y. Shibuta, Acta Materialia, 259 (2023) 119295. Moreover, LSTM is used to predict long-term trends in physical properties from short-term MD simulations. Latent vectors are extracted from coordinates of MD simulations using graph convolutional network (GCN). LSTM learns temporal trends in latent vectors and make one-step-ahead predictions. Recursive use of predicted values enabled long-term prediction from just the first 20 snapshots of the MD simulation.  K. Noda, Y. Shibuta, Journal of Physics: Condensed Matter, 36 (2024) 385902. Generative adversarial network (GAN) is used to generate heat flux akin to MD data. The heat flux generated by GAN closely resembled the one obtained through MD simulations. The GAN not only captured the external characteristics of the heat flux but also exhibited an understanding of its fundamental properties, including its periodic vibrations and the autocorrelation function governing thermal conductivity.  Q. Kong, Y. Shibuta, Journal of Physics: Condensed Matter, 36 (2024) 195901. Machine Learning Approach to Atomic Configuration of MD simulation and Related Materials Properties In principle, only coordinate and velocity of atoms are directly obtained from MD simulation. Primary data must be translated into interpretable information in the post-processing. We have performed automated analysis of atomic configuration of MD simulation based on machine learning (ML) approach with 3D convolutional neural network.  T. Fukuya, Y. Shibuta, Computational Materials Science, 184 (2020) 109880. ML methods was used to predict the mechanical properties of high-entropy alloys (HEAs). A database of a tensile test of 900 HEA single-crystal samples was established by MD simulation. Eight ML models were compared for the binary classification learning tasks and the kernel-based extreme learning machine (KELM) model outperformed others for the prediction of yield stress and Youngfs modulus.  L. Zhang, K. Qian, B.W. Schuller, Y. Shibuta, Metals, 11 (2021) 922 (in collaboration with Chongqing University, China, and Imperial College London, UK) Large-Scale MD Simulation of Nucleation and Microstructure Formation (collaborative work with Kyoto Institute of Technology and Hokkaido University, Japan) More than 10 billion atoms can be handled in a micrometer-scale system by large-scale MD simulations performed on GPU supercomputer. Nucleation and solidification from an undercooled melt and subsequent microstructure formation are spontaneously achieved.  Y. Shibuta, S. Sakane, E. Miyoshi, S. Okita, T. Takaki, M. Ohno Nature Communications, 8 (2017) 10. (press release)  Y. Shibuta, S. Sakane, E. Miyoshi, T. Takaki, M. Ohno Model. Simul. Mater. Sci. Eng., 27 (2019) 054002. Grain growth kinetics under the anisotropic grain boundary properties is investigated by large-scale and long-time MD simulations. Grain growth exponent obtained from MD simulation deviates from the ideal value since anisotropic effects in the grain boundary are inherently included in MD simulations.  S. Okita, E. Miyoshi, S. Sakane, T. Takaki, M. Ohno, Y. Shibuta Acta Materialia, 153 (2018) 108-116.  Y. Shibuta, S. Sakane, T. Takaki, M. Ohno Acta Materialia, 105 (2016) 328-337. Numerical Simulation for Pattern Formation Dynamics Pattern formation is the origin of generation of complex organizations in developmental biology. Belousov-Zhabotinsky (BZ) reaction is famous for a nonlinear chemical oscillator. Numerical analysis based on the Keener-Tyson model was performed for understanding the mechanism of unidirectional propagation of BZ reaction in triangle and pentagonal gel arrays.  S. Tateyama, Y. Shibuta, R. Yoshida The Journal of Physical Chemistry B, 112 (2008) 1777-1782. (in collaboration with the group of Prof. Ryo Yoshida at Dept. Mat. Eng. UTokyo) A phase-field (PF) model for electrochemical processes, in which cations were driven by an electrostatic potential coupled with a thermodynamic potential, was formulated on the basis of the PF model for binary alloys. Using this model, Cu electrodeposition from CuSO4 solution has been investigated.  Y. Shibuta, Y. Okajima, T. Suzuki Science and Technology of Advanced Materials, 8 (2007) 511-518. Bayesian Data Assimilation for Esimation of Materials Properties Data assimilation is a mathematical description for combining numerical simulations with observation data to estimate states and/or parameters of the system, as well as to enhance simulation accuracy. Recently, we employed this approach to the estimation of interfacial properties out of equilibrium condition.  Y. Nagatsuma, M. Ohno, T. Takaki, Y. Shibuta, Nanomaterials, 11 (2021) 2308. (in collaboration with Hokkaido University and Kyoto Institute of Technology, Japan) Moreover, data assimilation of in-situ monitoring chemical vapor deposition and phase-field simulation shed light on nucleation of a transition metal dichalcogenide (TMD)  X. Qiang, Y. Iwamoto, A. Watanabe, T. Kameyama, X. He, T. Kaneko, Y. Shibuta, T. Kato, Scientific Reports, 11 (2021) 22285. (press release) (in collaboration with Tohoku University, Japan) Metadynamics-Based Simulation for Free Energy Survey In general, one specific trajectory from MD simulation does not cover all the ensemble space. To overcome this problem, metadynamics is proposed to improve the efficiency of sampling by applying a bias to proper collective variables (CVs). We employed this approach to the estimation of solid-liquid interfacial energy out of equilibrium.  K. Ueno, S. Fukuhara, Y. Shibuta, Materials Transactions, 63 (2022) 209-216. Moreover, free energy surface (FES) of the cap formation process of carbon nanotubes is derived by metadynamics simulation in a two-dimensional CV space.  S. Fukuhara, Y. Shibuta, Nanoscale Advances, 3 (2021) 6191-6196. Acceleration of MD Simulation with Parallel CVHD Method (collaborative work with University of Antwerp, Belgium) The limitation in time and length scale is a major issue of MD simulation. An accelerated MD method for large system is developed based on the collective variable-driven hyperdynamics (CVHD) method. The key idea is to run CVHD in parallel with rate control and accelerate multiple possible events simultaneously.  S. Fukuhara, K.M. Bal, E.C. Neyts, Y. Shibuta Computational Materials Science, 177 (2020) 109581. Solid-Liquid Interfacial Properties from MD-Based Simulation Solidification microstructure of metallic materials is strongly affected by solid-liquid interfacial properties. However, it is not straightforward to measure these properties experimentally with a high degree of accuracy. Therefore, solid-liquid interfacial properties are estimated from MD-based simulations.  K. Ueno, Y. Shibuta, Computational Materials Science, 167 (2019) 1-7. Interaction of Graphenes with a Turbostratic Orientational Relationship (collaborative work with University of Cambridge, UK) It is well known that the AB stacking order between graphene layers in graphite is energetically stable. However, there is little information on the interaction between the graphite layers with a turbostratic orientational relationship (OR). Interaction of two rigid defect-free graphene sheets with various turbostratic ORs is investigated. It is revealed turbostratic orientations diminish the energy for translational displacement to zero.  Y. Shibuta, J.A. Elliott, Chem. Phys. Lett. 512 (2011) 146-150. Metal-Catalyzed Growth of Carbon Nanotubes and Graphene (collaborative work with Kumamoto University, Japan) It is empirically known that the yield and quality of the carbon nanotubes and graphene products strongly depend on a choice of carbon source molecules and additive. We have investigated methane dissociation on the nickel(111) surface and ethanol dissociation on transition metal nanoparticles to understand initial stage of graphene and carbon nanotube growth via a CVD technique by ab initio molecular dynamics simulation.  Y. Shibuta, R. Alifin, K. Shimamura, T. Oguri, F. Shimojo, S. Yamaguchi, Chem. Phys. Lett. 565 (2013) 92-97.  S. Fukuhara, M. Misawa, F. Shimojo, Y. Shibuta Chem. Phys. Lett. 731 (2019) 136619. |